Right, so you have your desired channels marked out on your core, cut them out and stick em to your rocker to act as the 'male' part of the mould, is that what your saying? Is how i've thought of doing it in the past, but i'm guessing it's a lot more complicated than it sounds! As for the environmental thing i couldn't give two hoots as it's a load of old bollocks anyway.BWD wrote:No need to carve like michelangelo when it can be done more like origami.

well, origami plus glue...

"Cut" the planes of the core - thin saw (or a razor, with foam)

"Paste" them into the desired orientation nutella or peanut butter (epoxy is not environmental!!!).

Proceed as usual.

Theoretically with a wood strip core you could omit the "cut" step, if you manage to not glue certain strips together along their whole lengths, but this may be easier said than done.

Too many channels are destroying the ozone!

Undecided about Paulownia or foam? Ideas?

-

sijandy

- Very Frequent Poster

- Posts: 621

- Joined: Mon Sep 03, 2012 12:36 pm

- Style: freestyle

- Gear: kites and boards

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 0

Re: Undecided about Paulownia or foam? Ideas?

-

BWD

- Very Frequent Poster

- Posts: 3849

- Joined: Thu Jun 05, 2003 3:37 am

- Has thanked: 2 times

- Been thanked: 81 times

Re: Undecided about Paulownia or foam? Ideas?

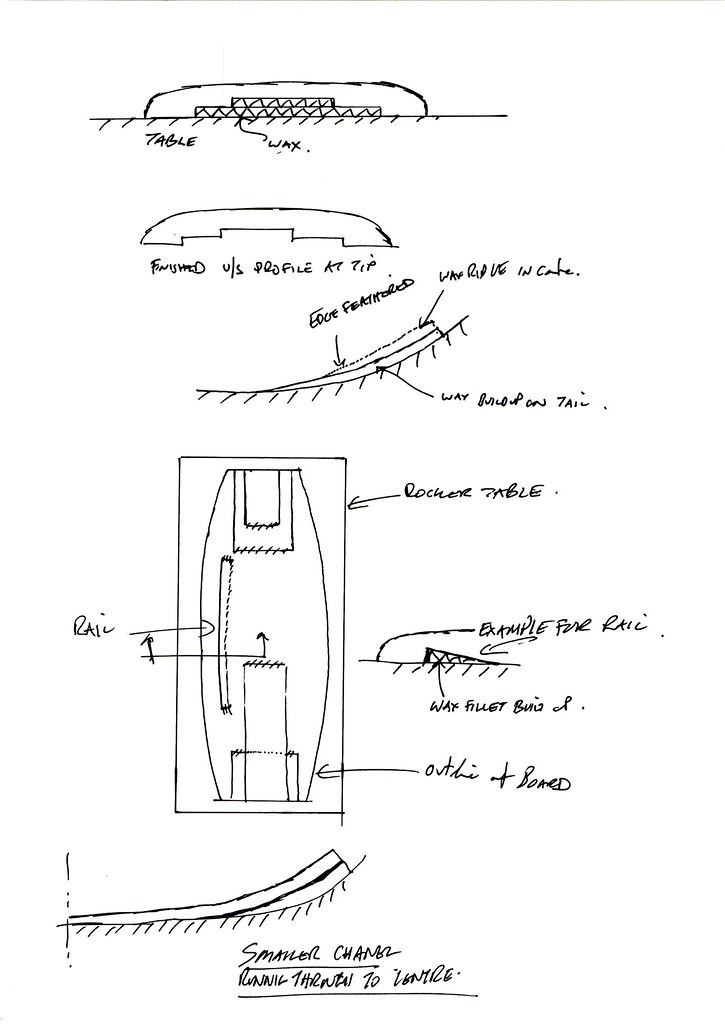

My rocker table is gender neutral, but essentially we are in agreement.

You could get good results forming the channels on a rocker table (or even on a flat surface), just secure the core to the surface and use some tiny devils to prop the parts up how you want them.

The tips (and the fillets of goo) must be thin enough to preserve the flex you are after, keep in mind adding "corrugations" and glue affects stiffness.

Doing it on the rocker table helps make sure you will still hit the rocker you want.

By the way the glassing is ...interesting.

A vac setup would help, and/or you can use spray adhesive (3m no. 77) to tack the glass to the channels.

I am giving it up, I hope the grumpy shaper's guild doesn't disappear me.

You could get good results forming the channels on a rocker table (or even on a flat surface), just secure the core to the surface and use some tiny devils to prop the parts up how you want them.

The tips (and the fillets of goo) must be thin enough to preserve the flex you are after, keep in mind adding "corrugations" and glue affects stiffness.

Doing it on the rocker table helps make sure you will still hit the rocker you want.

By the way the glassing is ...interesting.

A vac setup would help, and/or you can use spray adhesive (3m no. 77) to tack the glass to the channels.

I am giving it up, I hope the grumpy shaper's guild doesn't disappear me.

- Attachments

-

- compositesandwich.png (10.32 KiB) Viewed 1450 times

-

sijandy

- Very Frequent Poster

- Posts: 621

- Joined: Mon Sep 03, 2012 12:36 pm

- Style: freestyle

- Gear: kites and boards

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 0

Re: Undecided about Paulownia or foam? Ideas?

hmmm... i'm now more confused than before - maybe i'm just thick but i don't understand your picture at all, so much so that i can't even forge a question that doesn't sound retarded.

-

chrislandy

- Rare Poster

- Posts: 39

- Joined: Wed Apr 02, 2014 6:48 pm

- Gear: Wakeboard

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 0

Re: Undecided about Paulownia or foam? Ideas?

This is the basis of what I'm going to try on the next board but cut the core to allow the transitionsijandy wrote:hmmm... i'm now more confused than before - maybe i'm just thick but i don't understand your picture at all, so much so that i can't even forge a question that doesn't sound retarded.

-

BWD

- Very Frequent Poster

- Posts: 3849

- Joined: Thu Jun 05, 2003 3:37 am

- Has thanked: 2 times

- Been thanked: 81 times

Re: Undecided about Paulownia or foam? Ideas?

The picture is conceptually like looking at the end of the core while channels are being glued into place.

I found an old photo that is better, my 1st cut and paste job, crude especially at this stage, but the eventual result was pretty good.

Core profiled as usual, incisions cut with a pull saw freeing the channels, board attached to table, wedges and screws position the freed channels, goo glues it together. Remove, flip, repeat. Use tape and plastic to protect vs. epoxy spill/flash. White patch at left board corner shows what happens when the router sled is not aligned just right - that corner ended up too thin, so built it back up with epoxy bog.

Instead of so much bog along the channel edges on the deck side I could have glued in little strips of core wood and shaved them down for better cosmetics, but it was just an experiment, and I'd already had to bog the corner, oops, so didn't bother.

I found an old photo that is better, my 1st cut and paste job, crude especially at this stage, but the eventual result was pretty good.

Core profiled as usual, incisions cut with a pull saw freeing the channels, board attached to table, wedges and screws position the freed channels, goo glues it together. Remove, flip, repeat. Use tape and plastic to protect vs. epoxy spill/flash. White patch at left board corner shows what happens when the router sled is not aligned just right - that corner ended up too thin, so built it back up with epoxy bog.

Instead of so much bog along the channel edges on the deck side I could have glued in little strips of core wood and shaved them down for better cosmetics, but it was just an experiment, and I'd already had to bog the corner, oops, so didn't bother.

-

sijandy

- Very Frequent Poster

- Posts: 621

- Joined: Mon Sep 03, 2012 12:36 pm

- Style: freestyle

- Gear: kites and boards

- Brand Affiliation: None

- Has thanked: 0

- Been thanked: 0

Re: Undecided about Paulownia or foam? Ideas?

Aaahhh....now i gotcha, was being a spaz. Looks good, i imagine that would come out similar style to the pic downunder put up earlier, brunotti i think. Although i would like to try something like this i'm initially more interested in longer channels running the length towards the rail edges to help with the upwind-ability on my heavily rockered boards which i think will involve a slightly different method. Do you do your layups one side at a time?

-

BWD

- Very Frequent Poster

- Posts: 3849

- Joined: Thu Jun 05, 2003 3:37 am

- Has thanked: 2 times

- Been thanked: 81 times

Re: Undecided about Paulownia or foam? Ideas?

Yep, deck first.

No vacuum usually.

Screws are quieter and hold the board down regardless of leaks or electricity.

You can put em through the blank outside the board's rails-to-be if you don't cut it out till later.

A sheet of 9mm birch plywood makes a great rocker table surface btw. Can be tuned to within a mm or better with a few well placed screws. Easy and inexpensive, replace when too many holes or resin globs.

I aim for economy of means, the caveman solution.

Probably could put lots of $$$s into tooling etc but would only makes boards come in a few 100g lighter.

For a rail channel you could router it in or glue up the core with a raised strip by a similar method to above. For a long center channel, just glue up core with a spacer under middle section.

I think a center channel that faded out forwards tips could help with what you want for upwind by lowering the effective rocker but leaving the rail rocker there to turn off of. This has been claimed at least.

No vacuum usually.

Screws are quieter and hold the board down regardless of leaks or electricity.

You can put em through the blank outside the board's rails-to-be if you don't cut it out till later.

A sheet of 9mm birch plywood makes a great rocker table surface btw. Can be tuned to within a mm or better with a few well placed screws. Easy and inexpensive, replace when too many holes or resin globs.

I aim for economy of means, the caveman solution.

Probably could put lots of $$$s into tooling etc but would only makes boards come in a few 100g lighter.

For a rail channel you could router it in or glue up the core with a raised strip by a similar method to above. For a long center channel, just glue up core with a spacer under middle section.

I think a center channel that faded out forwards tips could help with what you want for upwind by lowering the effective rocker but leaving the rail rocker there to turn off of. This has been claimed at least.

- downunder

- Very Frequent Poster

- Posts: 2821

- Joined: Mon Jul 01, 2013 7:16 am

- Gear: building my own

- Brand Affiliation: None

- Location: Perth, Australia

- Has thanked: 153 times

- Been thanked: 161 times

Re: Undecided about Paulownia or foam? Ideas?

As before, a lot of useful info, thank youBWD wrote: Core profiled as usual, incisions cut with a pull saw...

Ok, what is a pull saw? When you say thin cut - thin saw, the only thin cut I think is with this:

On the $$$ side of the things the whole idea is to make boards with a minimal tooling.

-

BWD

- Very Frequent Poster

- Posts: 3849

- Joined: Thu Jun 05, 2003 3:37 am

- Has thanked: 2 times

- Been thanked: 81 times

Re: Undecided about Paulownia or foam? Ideas?

think cheap, $20 but if you pay $40 you get the real blade from japan, thinner kerf and stays sharp for a long time. It will go through wood, carbon, glass like a knife through butter -for a while at least. A long while if you don't use it to cut a boat apart like I did. The cheap version is adequate for soft woods.

think cheap, $20 but if you pay $40 you get the real blade from japan, thinner kerf and stays sharp for a long time. It will go through wood, carbon, glass like a knife through butter -for a while at least. A long while if you don't use it to cut a boat apart like I did. The cheap version is adequate for soft woods. The good version is also sometimes called razor saw.

It's hard not to bleed a little when you use it casually.

It's an awesome tool, right up there with the low angle block plane, if you're into wood.

But for this most any hand saw would probably do fine.

- downunder

- Very Frequent Poster

- Posts: 2821

- Joined: Mon Jul 01, 2013 7:16 am

- Gear: building my own

- Brand Affiliation: None

- Location: Perth, Australia

- Has thanked: 153 times

- Been thanked: 161 times

Re: Undecided about Paulownia or foam? Ideas?

^^^

yep, seen those...They got some kick a.s big ones. But still thinking the above machine would work faster since the blade is for up-down cutting as well.

I earnestly think the Brunotti board was CNC-ed from one single block of wood.

Judging that coz the glass on top is light and there are no visible layers of wood to keep the rocker in. It was stolen from me some time ago so no way to check it again.

Infact my hart stopped the other day when one rider used exactly the same board, but than the serial number was different:) his was 89, mine 146 of 150 made on the Planet.

yep, seen those...They got some kick a.s big ones. But still thinking the above machine would work faster since the blade is for up-down cutting as well.

sijandy wrote:Aaahhh....now i gotcha, was being a spaz. Looks good, i imagine that would come out similar style to the pic downunder put up earlier, brunotti i think. Although i would like to try something like this i'm initially more interested in longer channels running the length towards the rail edges to help with the upwind-ability on my heavily rockered boards which i think will involve a slightly different method. Do you do your layups one side at a time?

I earnestly think the Brunotti board was CNC-ed from one single block of wood.

Judging that coz the glass on top is light and there are no visible layers of wood to keep the rocker in. It was stolen from me some time ago so no way to check it again.

Infact my hart stopped the other day when one rider used exactly the same board, but than the serial number was different:) his was 89, mine 146 of 150 made on the Planet.

Who is online

Users browsing this forum: No registered users and 213 guests